WHAT IS CWT?

CWT is an indirect heating system that is designed to heat crude oil for processing purposes.

CWT patented technology uses steam to indirectly heat crude oil, making it much safer, more cost effective, and better for the environment than the traditional firetube systems that are currently used today.

HOW CWT WORKS.

How It Works.

The CWT indirect heating system is a two-phase thermosiphon that transfers heat to the process through an innovative technology called the Heat Driven Loop (HDL).

A mixture of water and glycol is contained in a vacuum state and heated by a low-pressure flame bed. The water changes to steam at a lower temperature due to the vacuum state.

The steam is then allowed to rush towards the process which requires the heat through a system of tubes (heat exchanger). The steam then expends its energy and condenses back to liquid form.

The liquid (Water) then gravity feeds back to the evaporation chamber where it will again be recharged back to steam.

This continuous loop of transferring energy from a flame bed to process fluid, using steam and the latent heat of vaporization, is the key to the CWT system.

CWT: The Process System

Utilizes an ASME Sec IV steam boiler

Closed system under vacuum with no make-up water

Low pressure flame bed supplies heat to the water/glycol mixture causing the water to boil almost instantly which results in an exceptional response time

Uses a process line temperature sensor ensuring exact control

Steam temperature self-adjusts to 250F

Uses the latent heat of vaporization making it more efficient ASME Sec IV controls ensure safety

Benefit of CWT Indirect Heating vs. Traditional Firetube Methods

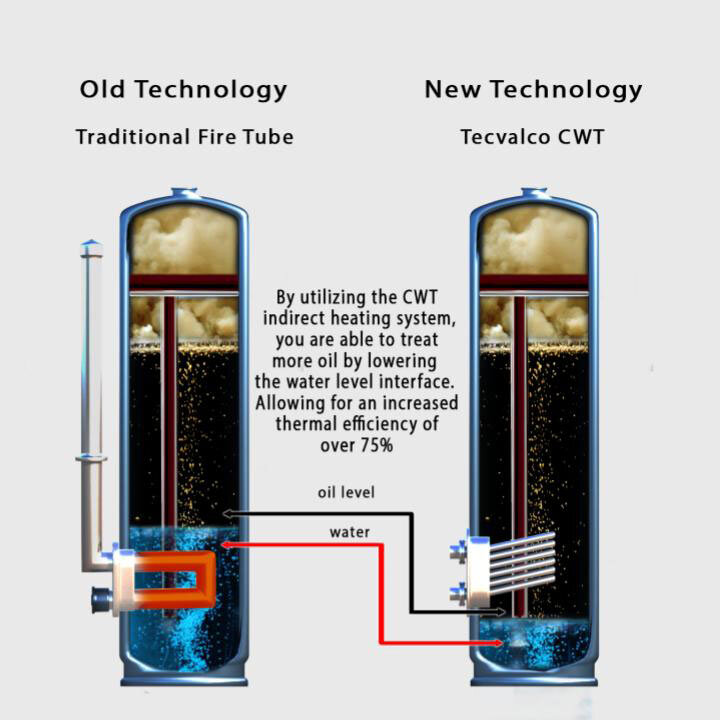

One of the components of CWT indirect heating system is the Heat Exchanger. The steam coils of the heat exchanger can be submerged directly in the oil emulsion area. This allows oil producers to lower the water-oil interface level in the treater, which will allow for greater treater capacity and the ability to treat more oil.

CWT Heat Exchanger

Another added benefit to the CWT system is that by utilizing steam through the heat exchanger coils we do not see the high skin temperature and scale build up that you would see using a firetube. With no scale build up on the steam coils, you have true consistent heat transfer throughout the exchanger. Resulting in an increase in efficiency, longer life of the exchanger along with reduced operator and maintenance costs.

CWT Heat Exchanger vs. Firetube

CWT Exchanger.

CWT Exchanger pull after 2-1/2 years of service for inspection. Heat exchanger green coating was unharmed and looked the same as it did when it was first installed into the treater.

Firetube.

Firetube after less than two years of service. Notice all of the corrosion and heat degradation to the tube. This will most certainly end with a firetube failure.

Not a question of If you will have a firetube failure, but a question of When.

Remove the risk.

Eliminate firetube failures with the Tecvalco CWT Indirect Heating system.

CWT Heat Exchanger vs. Firetube

CWT Heat Exchanger New Technology

Purpose designed for tank and treater applications

ASME Sec VIII flange and tubes

Approved for use in the US & CA

Standard models with 112 ft² and 149 ft² of tube transfer area (will replace 0.5 mm btu/hr and 1.0 mm btu/hr fire tubes)

Uses latent heat transfer (condensing steam)yielding a uniform temperature profile across the entire exchanger

Multiple tube arrangement utilizes a larger x-sec area of the vessel (16 5/8” wide), yields superior heat distribution

Relatively low volumetric displacement of fluid for given heat transfer rate (5.5 ft3 for 6x20 treater)

Firetube Traditional Method

Poor thermal efficiency (industry studies indicate 40-45% at best)

Hot section is subject to extreme temperatures and direct flame impingement

High temperatures cause premature gasket failures

High skin temperatures mean that the oil cannot be in direct contact with the tube, must heat the water phase (increases vessel size)

High temperatures cause the water in contact with the firetube to boil which leads to tube scale (mineral deposits)

Tube scale reduces heat transfer and results in increased localized skin temperatures and tube degradation

High temperatures reduce the life of corrosion inhibiters (coatings)

Reduced heat transfer requires increasing the firing rates, which compounds the problems

Tube failure is imminent

Heater Gas Consumption.

The CWT indirect heating system has a major increase in thermal efficiency. The CWT system boasts thermal efficiency between 70 and 80 percent. (third-party tested) With the CWT system running on low pressure of (2oz) of well head or utility gas the CWT system has a reduction of fuel gas consumption by up to 50 percent and the increase in thermal efficiency means that there is less fuel consumption and less greenhouse gas emissions emitted to the atmosphere.

Vacuum State HDL

The vacuum state that the CWT system runs on also reduces corrosion as there is very little to no oxygen inside the heat driven loop (HDL) system and allows the heater to operate at less than 15PSI and as high as 250F.

GENERAL PURPOSE AREA

The CWT Heater is located in a general-purpose area. No external electricity required, has very simple controls, and does not use pumps or motors.

Shrink your pad size by installing a CWT Indirect Heat System

Unprecedented Spacing Exception.

NORTH DAKOTA INDUSTRIAL COMMISSION REVIEW AND ORDER

October 24, 2012 NDIC grants similar approvals that are standard in Saskatchewan CA

By utilizing the CWT Indirect heating system you may now treat oil 21 feet away from the production tanks rather than the 125 feet from production tanks that is currently standard in ND today.

This was a very significant ruling for future activities.

Located outside the secondary containment in a General Purpose location.

This allows for direct heating of oil tanks or Heater treaters with low gas production. (GOR)

State of North Dakota Spacing Exemption Order

CWT Indirect Heating System Benefits Of Smaller Pad Size

By utilizing the CWT indirect heating system oil producers will be able to significantly shrink their location (pad) size. This means there will be over all cost savings in these areas .

Production Equipment

Less piping cost

Less metal containment cost

Less electrical cost

Less labor cost

Pad Size-Smaller Lease

All raw land purchased

Less dirt work (remediation)

Cost and labor

CWT CURRENT APPLICATIONS

(VHT) Vertical Heater Treater

Safe, Silent, Long Life

No moving parts like motors and pumps

Silent operation

Low pressure (2 oz) utility or well head gas supply

Flame arrested air intake built to US Coast Guard standard

ASME Section IV vacuum boiler design

Operates on 26 psig vacuum to 250 degrees F

Certified Non-incendive electrical control system

Operates 21 feet from tank in general purpose area

Reduces emissions and fuel gas consumptions by up to 50 percent

Operates at 75 to 80 percent thermal efficiency

No electricity required

No special boiler certifications to operate in class one zone two hazardous location

(HHT) Horizonal Heater Treater.

We Have seen an increase in horizonal treater firetube failures. With a horizonal treater able to treat more overall fluid than a vertical treater can. This makes the horizonal treater firetube failures catastrophic.

By utilizing the CWT Indirect heating system an operator can eliminate this problem. By heating the oil indirectly and pulling out the firetube and inserting the CWT systems heat exchanger, you eliminate the thermal degradation that causes most of the firetube failures.

HHT Options.

CWT Dual Unit Benefits.

With CWT we can now heat two vessels with one CWT unit utilizing our dual unit system. This is an added cost benefit to the producer and can divide the cost of the system over two wells.

CWT Dual Unit Layout

CWT TANK HEATING

TANK HEATING OPTIONS.

Elite Financial Services.

At Elite we are able to offer financing on our Elite products.

Easy to use no hassle financing

Rent to own

Flexible terms

Custom financing to fit your company’s needs

What We Currently Offer.

385,000 BTU Unit

770,000 BTU Unit

*We are working on a 2,000,000 BTU Unit.

CWT OVERVIEW OF BENEFITS

45 to 50-year boiler life.

15 to 20-year heat exchanger life.

Ability to use spacing exemption reduces pad size (Cost Savings).

No moving parts like motors and pumps.

Silent operation.

Low pressure uses 2oz of well head gas or utility gas to operate.

Reduces GHG emissions by up to 50%.

No electricity required to operate.

Operates at 75% to 80% thermal efficiency.

Certified nonincendive electrical control system.

Flame arrested air intake built to US Coast Guard standard.

Ability to lower water level in treater to treat more oil.

Heat oil indirectly vs heating water to heat the oil.

A much greater ROI over the life of a well.

Ability to retrofit existing locations. Plug and play.

Eliminate firetube failures forever.